Why Fluid-Lok?

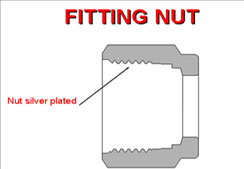

Tube Fittings are internally silver plated for dry lubrication purpose which result

in reduction of torque during assembly

and also extending Fittings life by preventing galling across wide range of

temperatures.

|

|

|

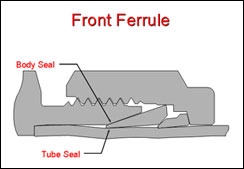

Hardness of the Raw material used for the Ferrules is higher than the hardness of

the tube recommended and precision machining combined with sharp uniform biting edge

ensures precision leak free connection between Tubes and Body.

The primary seal points of a twin ferrule system are:

|

|

|

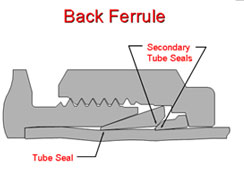

Precision machined Back Ferrules ensures a firm mechanical and vibration free grip

on the tube.

The secondary seals for a twin ferrule system are:

|

|

|

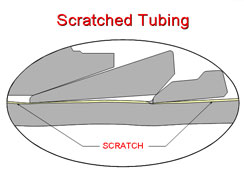

The front ferrule is a compression seal and may not seal some tube imperfections

(scratches, weld seams, etc.). |

|

|

BURST PRESSURE TEST

FLUID-LOK Tube Fittings undergoes Burst pressure test. The details of Test

Result are as under:

|

|

TUBE STICK FACTORS |

• THIN WALL TUBING • SOFT TUBING • DULL TUBE CUTTER • EXCESSIVE DEBURR • OVERMAKE FITTING • LARGE TUBE OD • MULTIPLE REMAKES • FITTING TOLERANCES |

Site Developed & Promoted by Advent Infosoft Pvt Ltd.